Fully automatic saw with optional workpiece

length measurement

Sawing technology + CFMcurve Chamfering with Curve Machining

Precision system for complex processing

of tubes and solid material.

Cutting and end-machining

The ACS+CFMcurve production system automatically saws master lengths/fixed lengths into workpieces of any length and transfers these automatically to a subsequent machining process, such as end machining of both ends. The extensive range of machining options for this system includes turning, chamfering, thread cutting, axial machining, radial machining, milling, drilling (center drilling, radial drilling), profile turning, groove cutting, radius chamfering and angled chamfering. All this turns the production of precision shafts into child’s play!

From cutting tubes to contouring edges

Whether you're manufacturing camshafts, bushings, airbag cartridges, shock absorbers or precision shafts...

With RATTUNDE systems you’ll produce sophisticated products of outstanding quality!

Technical Functions

- Production system for single- and multiple-cut sawing

- Wall thicknesses from 0.5 mm to solid material

- Optional – Extraction of machining chips directly at the source (sawing)

- CNC production system

- Ultra-dynamic servo drives

- Fully automated production process

- Material feed via bundle-loading magazine

- Automatic separation and positioning of the initial material

- Minimal set-up and unit costs thanks to minimal cycle times

- Optimal process reliability in production

- Maximum reliability and flexibility in production

- User-friendly screen interfaces and clearly structured menu navigation

- Job-based production process:

- creation, storage and administration of job lists, products and cutting data

- workpiece parameters and machine settings are loaded fully automatically and processed

- evaluation and analysis of job-related production and cutting data

- contactless material edge detection for material trim-cut and tag ends ≥ 0 mm

- Production of up to 3 different workpiece lengths within a single master length

- Defined outward transfer of workpieces via 3 possible material outlets

- Length measurement single and multiple cut

- Automatic workpiece length correction

- Optimization of energy and compressed air consumption via product-related settings

- Defined monitoring of the saw blade and saw blade drive

- Crash monitoring and analysis

- Monitoring of tension on the clamping tools

- Clamping force continuously adjustable

- Defined outward transfer of workpieces according to individual parameters, when e.g.

- workpiece lengths are incorrect

- clamping errors occur

- the saw torque is outside the target range

- a cut is incomplete

- Compliant with CE requirements as well as applicable directives and guidelines of the European Union and North America

- Integrated system for the most demanding end machining

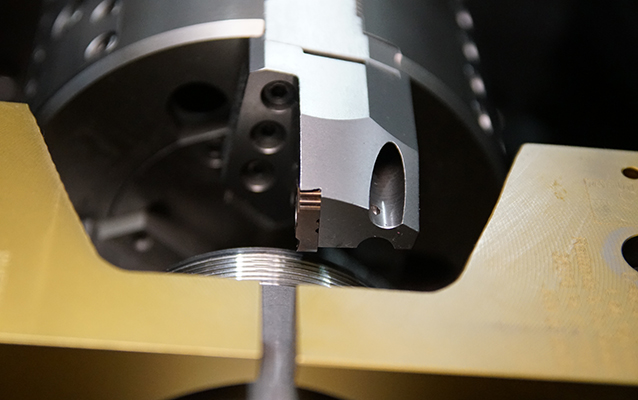

- End machining with 2 CFMcurve chamfering heads and 3 cutting tool holders with CNC supports (RATTUNDE patent)

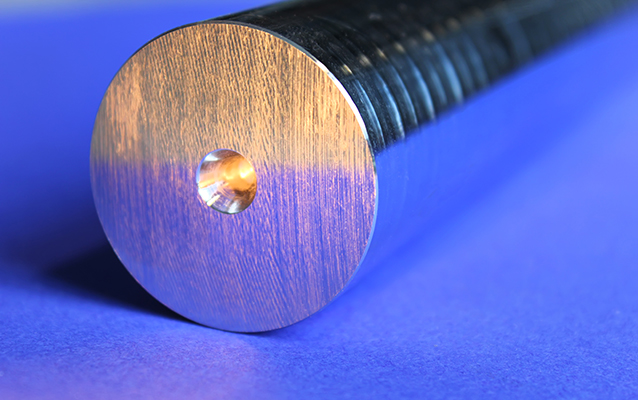

- For complex machining tasks (e.g. inside groove/outside groove, facing with inside or outside deburring, inside/outside thread, outside chamfer with radius/inside chamfer with radius, center drilling, etc.)

- Optional – Extraction of machining chips directly at the source (chamfer)

- Optimal workpiece positioning and centric clamping of the workpieces to the end-machining heads (horizontally and vertically 0.001 to 0.1 mm)

- Central monitoring and operation of the cutting tools and machining parameters

- Workpiece counter

- Cutting area

- Torque

- Tool wear

- Central monitoring of workpiece clamping on the CFMcurve clamp

- Centralized entry and administration of limit values

- Clamping force continuously adjustable

- Length measurement for each workpiece after chamfering

- Automatic workpiece length correction

- Automatic and defined outward workpiece transfer if:

- the previously defined tolerances are exceeded

- clamping errors occur

- the chamfering torque is exceeded or not reached

- Service life extension of the cutting tools via automatic shifting of the tool edge (no manual adjustment of the cutting tools required)

- Changing the machining length for the inside and outside chamfers during the machining process

- Select and define precision machining

- Definition of the transitions between chamfers, facing and outer wall with radius or facet

- Definition of various machining tasks and machining lengths for both workpiece sides and simultaneous machining (e.g. contour and thread)

- Thread cutting with chip-breaking stroke (inside and outside thread)

- Set-up of the position and depth of inside and outside grooves

- Changing the contour machining direction

- Create contours with different parameters for each operation

- Freely select chamfer angles or multiple chamfers for contours

- Free definition of the machining process (e.g. creation of a contour before or after the thread)

- Separate assignment of different thread pitches for both workpiece sides

- Enter the angularity (inside thread and outside thread) for both workpiece sides

- Cut the inside and outside thread with different infeed options

- Chip length reduction via input parameters

Technical specifications

| Diameter range | 10 – 105 mm |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 7 – 1000/2000/2500/ 3000 ... 6500 mm |

| Production accuracy of the workpiece length, reference dimension Dₐ = 50 mm |

±0.025 mm s = 0.01 mm |

| Maximum production output in single-cut operation | 3150 pcs/h |

| Maximum mechanical power of the saw | 18 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools | 15 min |

| Time required for changing the CFMcurve tool holders | 12 min |

| Diameter range | 10 – 136 mm |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 7 – 1000/2000/2500/ 3000 ... 6500 mm |

| Production accuracy of the workpiece length, reference dimension Dₐ = 50 mm |

±0.025 mm s = 0.01 mm |

| Maximum production output in single-cut operation | 2050 pcs/h |

| Maximum mechanical power of the saw | 18 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools | 15 min |

| Time required for changing the CFMcurve tool holders | 12 min |

| Diameter range | 10 – 169 mm |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 7 – 1000/2000/2500/ 3000 ... 6500 mm |

| Production accuracy of the workpiece length, reference dimension Dₐ = 50 mm |

±0.025 mm s = 0.01 mm |

| Maximum production output in single-cut operation | 1800 pcs/h |

| Maximum mechanical power of the saw | 36 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools | 15 min |

| Time required for changing the CFMcurve tool holders | 12 min |

Need more information about our products?

Take this opportunity and get in touch with us!

We’ll be happy to advise you.

RATTUNDE Services at a Glance

Machines with innovative, trendsetting automation technology

“Into the future at high speed”