Fully automatic saw with optional workpiece

length measurement

back to the products

Sawing technology

Request

Sawing technology

+ CFM Chamfering

+ BDM Brush-deburring

Combined processing unit

- sawing machine,

chamfering system and integrated deburring machine

The ACS+CFM+BDM production system automatically saws master lengths/fixed lengths into workpieces of any length and transfers these automatically to a subsequent machining process, such as brush-deburring or end machining of both ends. The range of machining options for this system includes brush-deburring, edge contouring, chamfering of inside and outside chamfers, and facing.

Whether cutting, turning, chamfering or deburring...

Our combination of saw, deburring machine and chamfering machine

An all-in-one solution for cutting, deburring and end-machining tubes and rods.

Innovative, user-friendly and powerful

Technical Functions

- Production system for single- and multiple-cut sawing

- Wall thicknesses from 0.5 mm to solid material

- Optional – Extraction of machining chips directly at the source (sawing)

- CNC production system

- Ultra-dynamic servo drives

- Fully automated production process

- Material feed via bundle-loading magazine

- Automatic separation and positioning of the initial material

- Minimal set-up and unit costs thanks to minimal cycle times

- Optimal process reliability in production

- Maximum reliability and flexibility in production

- User-friendly screen interfaces and clearly structured menu navigation

- Job-based production process:

- creation, storage and administration of job lists, products and cutting data

- workpiece parameters and machine settings are loaded fully automatically and processed

- evaluation and analysis of job-related production and cutting data

- contactless material edge detection for material trim-cut and tag ends ≥ 0 mm

- Production of up to 3 different workpiece lengths within a single master length

- Defined outward transfer of workpieces via 3 possible material outlets

- Length measurement single and multiple cut

- Automatic workpiece length correction

- Optimization of energy and compressed air consumption via product-related settings

- Defined monitoring of the saw blade and saw blade drive

- Crash monitoring and analysis

- Monitoring of tension on the clamping tools

- Clamping force continuously adjustable

- Defined outward transfer of workpieces according to individual parameters, when e.g.

- workpiece lengths are incorrect

- clamping errors occur

- the saw torque is outside the target range

- a cut is incomplete

- Compliant with CE requirements as well as applicable directives and guidelines of the European Union and North America

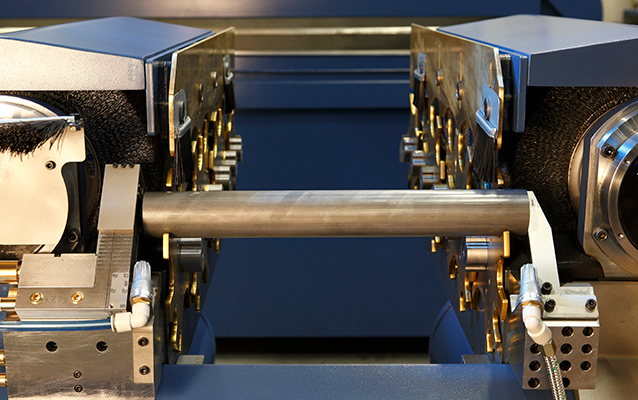

- Integrated end machining for single-cut applications

- Simultaneous machining of both workpiece ends

- Optional – Extraction of machining chips directly at the source (chamfer)

- Use of fixed and adjustable end-machining heads

- Optimal workpiece positioning and centric clamping of the workpieces to the end-machining heads (horizontally and vertically 0.001 to 0.1 mm)

- Central monitoring and operation of the cutting tools and machining parameters

- Workpiece counter

- Cutting area

- Torque

- Tool wear

- Central monitoring of workpiece clamping on the CFM clamp

- Centralized entry and administration of limit values

- Clamping force continuously adjustable

- Length measurement for each workpiece after chamfering

- Automatic workpiece length correction

- Automatic and defined outward workpiece transfer if:

- the previously defined tolerances are exceeded

- clamping errors occur

- the chamfering torque is exceeded or not reached

- Integrated brush-deburring system for single- and multiple-cut applications

- Variable brush speed settings

- Variable brush engagement depth settings

- Automatic workpiece length setting

- Transport of round and profile material in single- and multiple-cut sawing

- Workpiece transport via CNC transport disks

- Select special brushing and transport programs for various material qualities

- Rotation of the workpieces by 360° during brush-deburring

- Monitoring of brush drive performance

- Extraction of brush-deburring dusts via wet separator

Optimal performance right from the start!

Technical specifications

| Diameter range | 10 – 105 mm |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 100 – 1000/2000/ 2500 ... 6500 mm |

| Production accuracy of the workpiece length, reference dimension Dₐ = 50 mm |

Sawing + chamfering + brush-deburring ±0.025 mm s = 0.01 mm Sawing + brush-deburring (WITHOUT chamfering) ±0.05 mm Sg = 0.03 mm |

| Maximum production output in single-cut operation | 3050 pch/h |

| Maximum mechanical power of the saw | max. 18 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools |

15 min |

| Time required for changing the end-machining heads |

4 min |

| Diameter range | 10 – 136 mm |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 100 – 1000/2000/ 2500 ... 6500 mm |

| Production accuracy of the workpiece length, reference dimension Dₐ = 50 mm |

Sawing + chamfering + brush-deburring ±0.025 mm s = 0.01 mm Sawing + brush-deburring (WITHOUT chamfering) ±0.05 mm Sg = 0.03 mm |

| Maximum production output in single-cut operation | 2050 pcs/h |

| Maximum mechanical power of the saw | max. 18 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools |

15 min |

| Time required for changing the end-machining heads |

4 min |

| Diameter range | 10 – 169 mm |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 100 – 1000/ 2000/2500 3000 ... 6500 mm |

| Production accuracy of the workpiece length, reference dimension Dₐ = 50 mm |

Sawing + chamfering + brush-deburring ±0.025 mm s = 0.01 mm Sawing + brush-deburring (WITHOUT chamfering) ±0.05 mm Sg = 0.03 mm |

| Maximum production output in single-cut operation | 1600 pcs/h |

| Maximum mechanical power of the saw | max. 36 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools |

15 min |

| Time required for changing the end-machining heads |

Need more information about our products?

Take this opportunityand get in touch with us!

We’ll be happy to advise you.

Innovation, Productivity and Quality

RATTUNDE Services at a Glance

Machines with innovative, trendsetting automation technology

“Into the future at high speed”