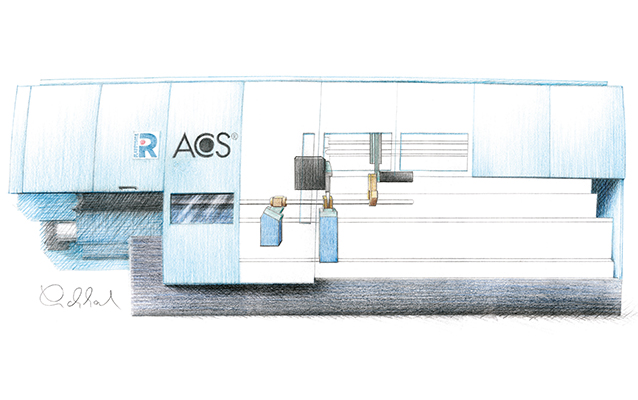

Fully automatic saw with optional workpiece

length measurement

back to the products

Sawing technology

Request

Sawing technology

(+ LM Length Measurement)

Fully automatic saw with optional workpiece

length measurement

Our systems are fully automated, high-precision circular cold saws. Our basic ACS® “sawing” version alone performs everything from single to septuple cut beautifully. Thanks to water-cooled servo technology, the material can be cut with continuously adjustable sawing power and extremely short sawing cycles, some of them less than one second. During the entire manufacturing process, the cutting speed, tool clamping pressure and sawblade vibration are continuously calculated and monitored.

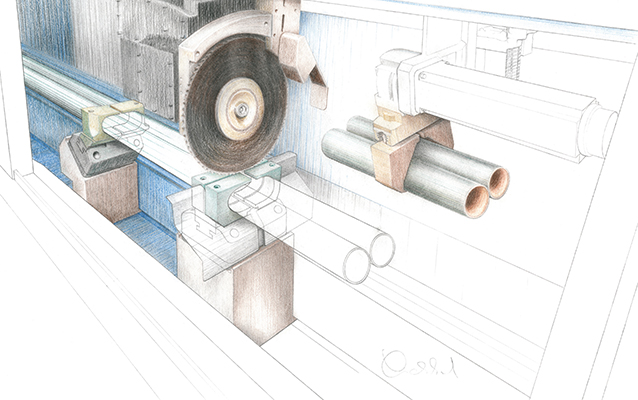

Powerful technology for cutting tubes, profiles and rods

Cutting, measuring and packaging...

A versatile high-production sawing system for steel, stainless steel, copper and copper alloys, and non-ferrous metals

Innovative, user-friendly and powerful

Technical Functions

- Production system for single- and multiple-cut sawing

- Wall thicknesses from 0.5 mm to solid material

- Optional – Extraction of machining chips directly at the source (sawing)

- CNC production system

- Ultra-dynamic servo drives

- Fully automated production process

- Material feed via bundle-loading magazine

- Automatic separation and positioning of the initial material

- Minimal set-up and unit costs thanks to minimal cycle times

- Optimal process reliability in production

- Maximum reliability and flexibility in production

- User-friendly screen interfaces and clearly structured menu navigation

- Job-based production process:

- creation, storage and administration of job lists, products and cutting data

- workpiece parameters and machine settings are loaded fully automatically and processed

- evaluation and analysis of job-related production and cutting data

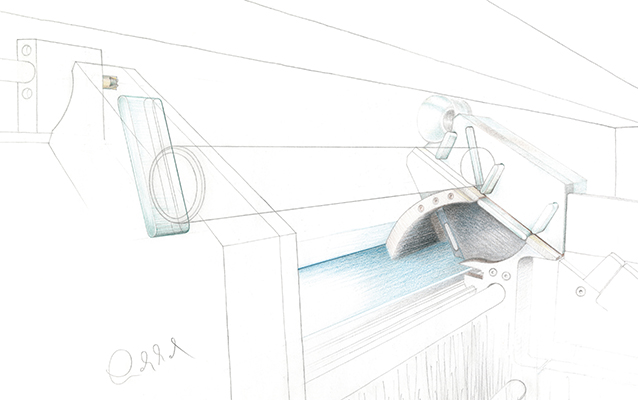

- contactless material edge detection for material trim-cut and tag ends ≥ 0 mm

- Production of up to 3 different workpiece lengths within a single master length

- Defined outward transfer of workpieces via 3 possible material outlets

- Length measurement single and multiple cut

- Automatic workpiece length correction

- Optimization of energy and compressed air consumption via product-related settings

- Defined monitoring of the saw blade and saw blade drive

- Crash monitoring and analysis

- Monitoring of tension on the clamping tools

- Clamping force continuously adjustable

- Defined outward transfer of workpieces according to individual parameters, when e.g.

- workpiece lengths are incorrect

- clamping errors occur

- the saw torque is outside the target range

- a cut is incomplete

- Compliant with CE requirements as well as applicable directives and guidelines of the European Union and North America

Optimal performance right from the start!

Technical specifications

| Diameter range | 10 – 120 mm |

| Multiple cut | 10 – 45 mm |

| Profile material | 10 x 10 – 100 x 100 mm 120 x 62 mm Multiple cut possible |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 3 – 1000/2000/2500/ 3000 ... 6500 mm |

| Production accuracy of the workpiece length reference dimension Dₐ = 50 mm |

±0.05 mm s = 0.03 mm |

| Maximum production output in: Single-cut operation |

3500 pcs/h |

| Double-cut operation | max. 7000 pcs/h |

| Triple-cut operation | max. 9000 pcs/h |

| Quadruple-cut operation | max. 12,000 pcs/h |

| Septuple-cut operation | max. 20,000 pcs/h |

| Maximum mechanical power of the saw | max. 18 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools | 7 min |

| Diameter range | 10 – 136 mm |

| Multiple cut | 10 – 60 mm |

| Profile material | 10 x 10 – 108 x 108 mm 195 x 48 mm Multiple cut possible |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 3 – 1000/2000/2500/ 3000 ... 6500 mm |

| Production accuracy of the workpiece length reference dimension Dₐ = 50 mm |

±0.05 mm s = 0.03 mm |

| Maximum production output in: Single-cut operation |

3500 pcs/h |

| Double-cut operation | max. 7000 pcs/h |

| Triple-cut operation | max. 9000 pcs/h |

| Quadruple-cut operation | max. 12,000 pcs/h |

| Septuple-cut operation | |

| Maximum mechanical power of the saw | max. 18 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools | 7 min |

| Diameter range | 10 – 169 mm |

| Multiple cut | 10 – 90 mm |

| Profile material | 10 x 10 – 120 x 120 mm 140 x 80 mm Multiple cut possible |

| Master lengths | 3000 – 6500/ 8000/9500/12,500/ 14,500/16,500 mm Bundle weight 5000 kg (8000 kg) |

| Workpiece lengths | 3 – 1000/2000/2500/ 3000 ... 6500 mm |

| Production accuracy of the workpiece length reference dimension Dₐ = 50 mm |

±0.05 mm s = 0.03 mm |

| Maximum production output in: Single-cut operation |

2700 pcs/h |

| Double-cut operation | max. 5400 pcs/h |

| Triple-cut operation | max. 6750 pcs/h |

| Quadruple-cut operation | max. 10,800 pcs/h |

| Septuple-cut operation | |

| Maximum mechanical power of the saw | max. 36 kW |

| Time required for saw blade change | 2 min |

| Time required for changing all clamping tools | 7 min |

Need more information about our products?

Take this opportunity and get in touch with us!

We’ll be happy to advise you.

Innovation, Productivity and Quality

RATTUNDE Services at a Glance

Machines with innovative, trendsetting automation technology

“Into the future at high speed”